8 August 2018

Offsite Insights – The Three P’s

Last week set the tone with ‘a defining moment’, looking at the terminology used and the varying types of an offsite approach. Today I would like to talk to the benefits an offsite approach can bring to a project, what I have come to call the three P’s.

Predictability, Precision and a Portfolio of works

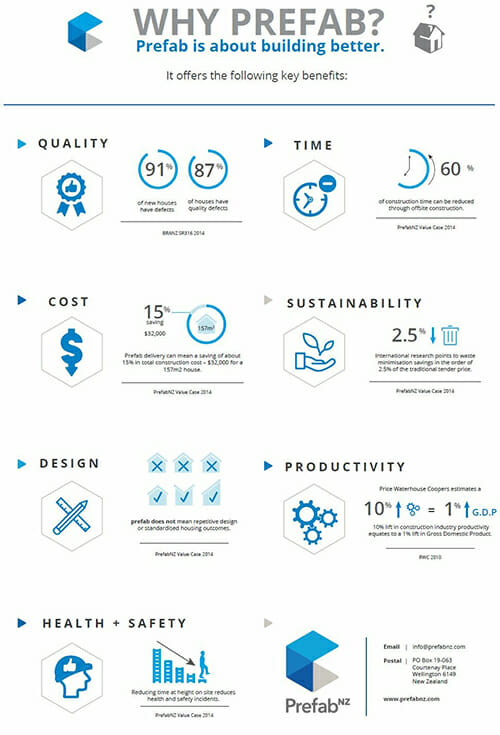

There is a wealth of information pertaining to the benefits of offsite approaches, providing data and figures around time and cost savings, also quality outcomes. PrefabNZ has produced a neat infographic for those who are after the numbers.

Image credit: Prefab NZ

As with any compilation of data sets, act with caution when quoting the figures and be sure you understand the context from which they are derived. With this in mind and with reference to Mark Farmers “Modernise or Die” and KPMG’s “Smart Construction” (both good reading), I prefer to keep it simple and pull the core benefits together under the banner of predictability and precision (we will get to the third P below).

Predictability

- Offsite approaches provide a reduced and reliable construction program – predictability.

- Concurrency of manufacturing and onsite works reduces construction program. Reduced construction program decreases exposure to inherent onsite risks – weather, trade interfaces, site activity, traffic movements, poor workmanship – thereby improving predictability.

- Application of manufacturing and production line processes improves predictability. Components are tracked through production line quality controls; quality inspections are complete prior to components leaving the factory.

- Critical path activities often run through the manufacturing process completed within a controlled environment. Again, less exposure to onsite risks and improved predictability.

Precision

- Precision captures the quality outcomes arising from the manufacturing and assembly process or production line quality. It is hard to remember a time when your Lego blocks didn’t fit, and if in fact they didn’t, it would typically come down to user error.

- Design resolution and coordination must be reached prior to manufacture, reducing redesign, rework and opportunity for (costly) changes onsite.

- The precision of production line quality control translates to improved efficiency of the building envelope.

- Precision provides for efficient use of (finite) resources, ultimately leading to reduced waste and reduced energy usage during the manufacture process.

- Let’s not forget the improved working conditions within a controlled environment.

Portfolio of Works – The Hidden P

- There is a hidden P, an additional benefit that only applies to a portfolio of works where a “product catalogue approach” can be adopted.

- A product catalogue approach is not dissimilar to a standard suite of typical room layouts, room data sheets, finishes specifications and schedules that we see commonly in the operating asset class. The idea behind this approach takes it one step further to incorporate approved fabrication drawings and agreed costs for product supply, effectively decoupling the manufacturing process of these products from the design phase.

- The benefits reach full potential resulting in further cost and program savings.

In summary, offsite approaches provide predictability and precision of time, cost and quality outcomes which in turn lead to enhanced environmental, sustainability, work health safety, and employee wellbeing outcomes. Think long term with a portfolio of works and the full potential of offsite can be realised.

Remind me again, why aren’t we asking for offsite?

James is an Associate Director with TSA Management, a project management and advisory services group. James has recently undertaken an extensive review of global offsite manufacturing practices and its impact on project procurement in the Australian built environment. James sees significant opportunity to harness the benefits offsite approaches can bring to a project – predictability and precision of time, cost and quality outcomes which in turn lead to enhanced environmental, sustainability, work health safety, and employee wellbeing outcomes